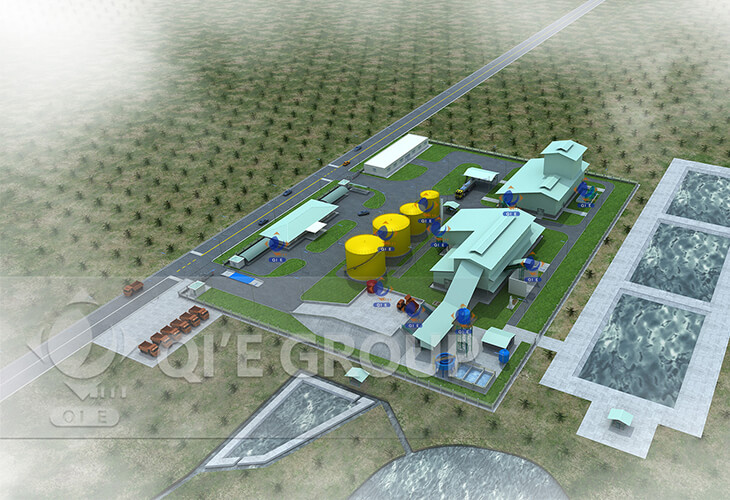

Palm Oil Processing Plant

This 5-10tph palm oil production plant includes all the processings of raw material reception, sterilization, threshing, digesting, pressing, clarification, kernel recovery and so on.

This 5-10tph palm oil production plant includes all the processings of raw material reception, sterilization, threshing, digesting, pressing, clarification, kernel recovery and so on.

Main section description:

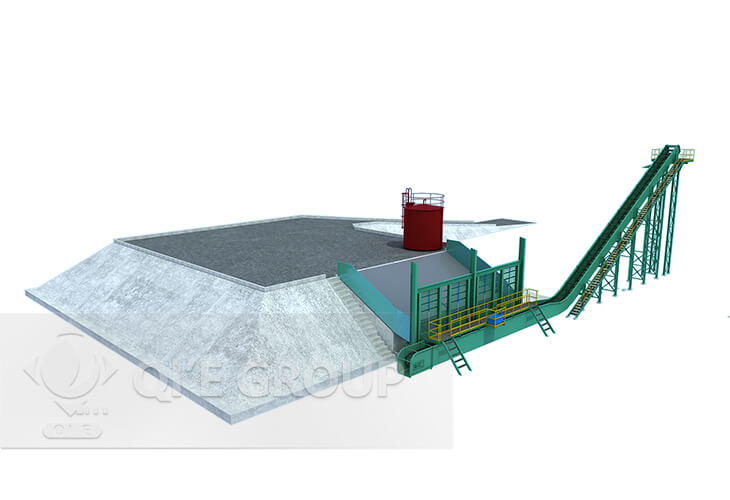

Raw material reception station: Used for loading fresh palm fruit brunch from plantation, transport to sterilizer.

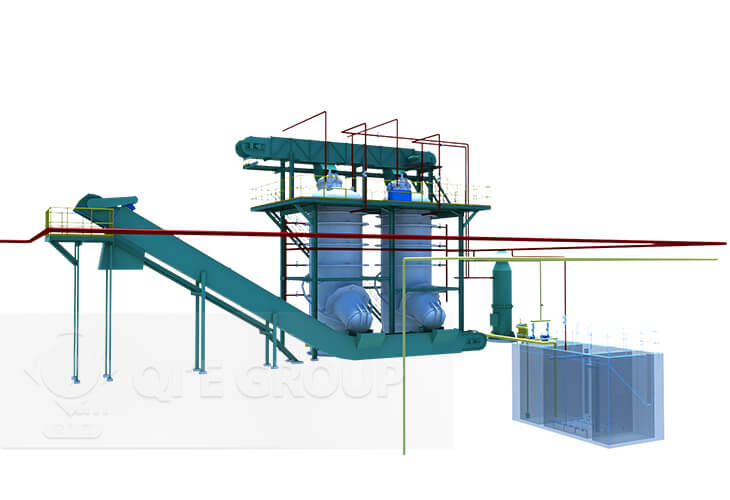

Sterilizing station: The purpose is to break the enzymes in fruit, and to avoid the increase of the FFA content in oil. At the same time, the high temperature makes the fruit soft.

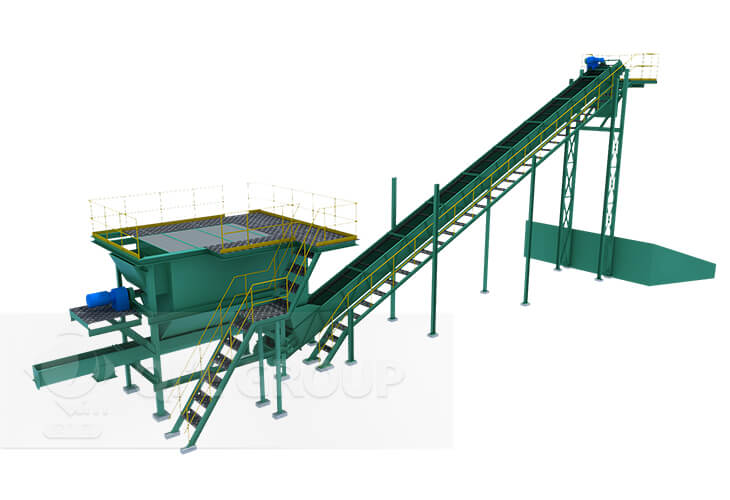

Threshing station: Used to separate palm fruit seeds and the empty palm fruit bunch.

Digesting & pressing station: They are mainly to crash palm fruit and then press. Crude palm oil can be got at this station.

Clarification station: The purpose is to remove some fiber, mud, or other impurities. After clarification, the purified palm oil can be directly sold or deeply refining.

Palm Kernel recovery: After pressing, the palm kernel and fiber mixture can be processed by further separation. After drying, the palm kernels are stored for deep processing, and the separated fiber and shells are used as the boiler fuel for providing steam.

Submit your enquiry,we will reply your quote within 24 hours.

Submit your enquiry,we will reply your quote within 24 hours.

Lianhua Street and Mudan Road,High-tech development zone, Zhengzhou City,Henan Province, China

Lianhua Street and Mudan Road,High-tech development zone, Zhengzhou City,Henan Province, China